Towards the end of last year, I came across an interesting circuit board on eBay. It was the CY7C68013A-56 EZ-USB development board – made by Lcsoft. Perhaps made is too strong a word, let’s say “designed” by Lcsoft, and copied by the myriad of asian suppliers. Anyway, it was less than AU$8 including shipping, so I ordered one. In due course, it came, but by then – as usual – I was tied up with other things.

Over the last couple of days, I was sorting things out, and I pulled out my Thurlby LA-160A Logic Analyzer from my cupboard. This logic analyzer was bought at great expense back in either 1985 or 1986. This one was badged by RS Components and was 16-bit capable, with various clock and trigger inputs – very versatile and economical at the time, compared with others that there were available and completely unaffordable, at least to a small business.

I was doing repairs on computers at the time, mainly Commodore 64’s and the IBM PC/XT clones. From memory, it didn’t get used a lot, and still has the plastic that covered the display. Being on a small budget, I elected to make the data pods for it instead of buying them. Ok – to stop digressing, I powered the LA-160A up and could see the display go through a check of all the segments, then LA160A .32 was displayed, telling me that it says that it is a LA-160A and the rom version is 32. Shortly afterwards, it said ready – but then a short while later, started checking the display again, then coming back to LA160A…

It looks like something is slightly amiss with it, so I had a quick check of Google, as we usually do, and found an article about the Nicad battery, and how it could leak. Definitely after 30 years or so, a Nicad battery will most likely have self-destructed, so it was time to open it up and take a look.

Nicad failure

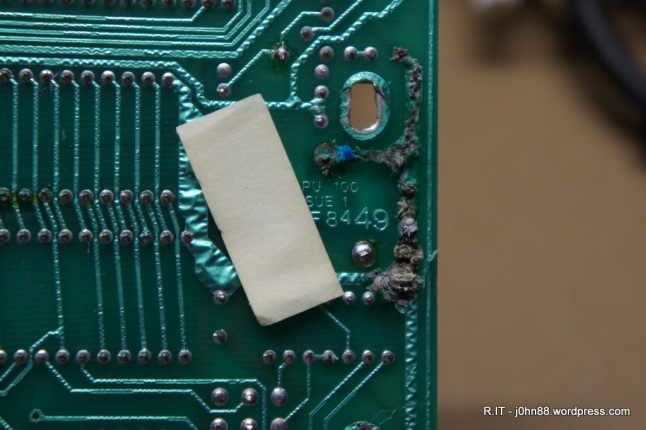

For sure, the battery looked a bit worse for wear – the negative terminal was corroded. Not only that, it looks like the electrolyte leaking out of the battery has travelled quite a distance.

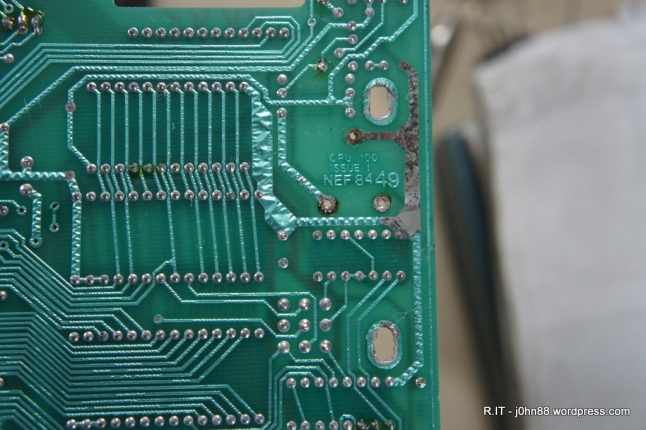

Under the board

Here the tracks under the battery appear also to be corroded, as in eaten away under the PCB coating. I had to remove the battery, which was easier said than done – the positive terminals were easy to desolder, but the negative terminal wouldn’t. I did manage to get it out finally and then it was time to inspect the damage.

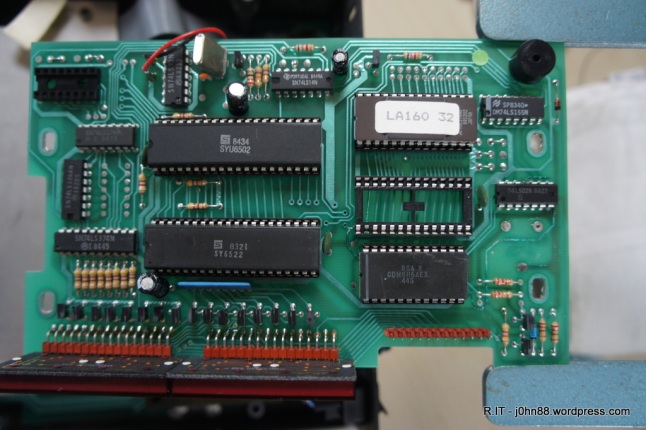

LA-160A controller board

The top of the board shows where the electrolyte has followed the path of corrosion, a process called wicking where the liquid moves into small gaps, caused by corrosion. I could see that the corrosion has reached pin 11 of the 74LS02N chip on the right, then the track in the other direction has gone under the two resistors, under the 6116 static ram, then all the way to the empty 28-pin socket (for an option rom) where pin two is corroded.

The corrosion will not stop and must be cleaned. I cleaned the bottom of the board first, since there was not much to be done, except that the tracks were larger.

Corroded ground tracks cleaned (sort of)

I removed the 6116 chip, then desoldered the 74LS20 and both the 6116 socket and the option rom socket. After doing this, I continued the cleaning process – by using methylated spirits with cotton tips to clean the tracks that were corroded – to try to neutralize the electrolyte. Once it was dry, I used a small flat screwdriver, and a fibreglass pen to remove the majority of the corrosion, then cleaned again with metho. Once I was happy with it, I gave the board a clean using isopropyl alcohol cleaning wipes (as the metho leaves a white deposit).

controller board after cleaning

Now it looks better. I could see that the corrosion had been moving in the direction of the LA160 32 eprom, so it looks like I caught it in time to prevent any major damage.

The next steps to do will be as follows:

- Repaint the cleaned tracks with a PCB Resist Touch Up paint, preferably in green. This will protect the tracks.

- Refit the 24-pin ic socket for the static ram and install the 6116 chip again.

- Fit a 14-pin ic socket for the 74LS02N.

- Check if I have stock of the 74LS02N, if not – then order a couple – I like to keep spares.

- Check continuity for all connections relating to the damaged tracks. Jumper wires to be soldered in place as needed to fix damaged connections.

- Order a replacement battery 2.4V 100mAh. Nicad ones are not available, but a NiMH 2.4V 140mAh battery is available at one of my usual suppliers. If I do this, then I need to ensure that the logic analyzer is turned on every couple of months or so, to keep the battery charged up. It is usually a flat battery that starts leaking, plus of course – old age.

I have decided not to install a 28-pin option rom socket for the simple reason that I don’t have the LR-64 option rom for this logic analyzer. If I do get hold of one and want to install this, it would be a simple matter of installing the socket at that time. Also leaving the socket out would allow me to inspect the corroded tracks to confirm that the corrosion is no longer progressing.

By the way, the LA-160A will capture 16-bit data at 10MHz sampling rate. The little CY7C68013A board will be able to capture 8-bit data at 25MHz – an example of new technology at less than a hundredth of the cost of the LA-160A. For about $100 I could get a logic analyzer that can capture 34 bits at 125MHz – maybe that is for another day.

Anyway, this is part 1, with more to follow.

P.S. During my Google search, I found a site http://sonicsheep.com/Electronics/3-LA160%20Writeup.htm that talked about the battery and had a newer rom version 50 available for download, and from another site

http://k1.spdns.de/Vintage/Sinclair/Other%20Inventions/Other%20Electronics%20Products/

found a service manual for this LA-160A. To try out the version 50, I will need a 2764A eprom or perhaps a 2864A eeprom. The 2764A is uv-erasable, but I don’t have a uv eraser, so the 2864A being electrically-erasable would probably be better. Anyway, it depends on what is available and from where.

[Edit] After checking my stock of integrated circuits and finally finding a 74LS20N, I found that I had misread the IC and actually needed a 74LS02N, of which I do have plenty. Updated the above article with 74LS02N. I should wear my glasses.