In July last year, the local Eagnas importer had referred an inquiry to me. A man in Melbourne had a problem with his stringing machine. The machine is a Combo 3800 which is also sold by Eagnas as well as other companies. Anyway, the problem is that the machine reports a load cell cable error – which is a generic error that the readings from the load cell are out of range.

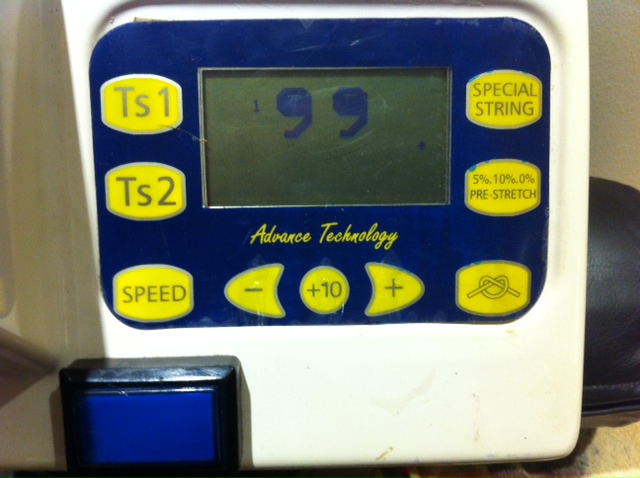

The man sent this photo to me of what it displays when he does the +10 power on test. I.e. press and hold the +10 button down, then power on. It shows 99 – bad, which in my opinion very likely means that a transistor had failed causing the ADC to also fail. I told him the location of the transistor and ADC. He said that he had a friend who might be able to do the replacement for him and we left it at that.

Ok, around the end of January I was going through some old emails and I came across his, and wondered what had happened, so I asked him. It seems that he didn’t get anywhere with it other than getting the transistor and replacing it. Still the same error – so I said that the ADC replacement should fix it. Eventually after a few emails back and forth, he decided that it might be best to send it up to me, which in due course he did, arrived last Friday week. On that weekend, I had a look at it, found a broken wire, fixed that and after some measurement of signals concluded that the ADC had actually failed. The ADC was out of stock at the supplier, but it eventually arrived on Friday – all the way from Singapore.

On Sunday morning, I woke up a little early and thought that while everyone is asleep, that might be a good time to tackle the ADC replacement. The ADC is that flat chip next to the big chip. That flat chip is a 22 lead SOIC. The length of that chip is about the thickness of my little finger.

I use Chip Quik to help in removing these surface mount chips. The Chip Quik is a low temperature alloy that mixed with the existing solder. I put some flux onto the chip pins, then melt the Chip Quik onto the pins and go around a couple of times, then just lift the chip off the board. Takes only seconds! Then clean up the old solder and alloy with solder wick. Then clean with isopropyl alcohol wipes, add flux again – drop the new chip in place and ready to solder. To solder, I just need to tack on a couple of the pins on each corner – to stop it from moving around. Then add solder onto my iron and just wipe the iron tip across the pins. Do this a couple of times until each pin is wetted. Do the same for the other side. If any pins are bridged, just wipe the iron on the pins away from the chip. All done – ok not quite. I do this with the board removed from the machine, I had to then reassemble it into the machine which was a bit of a job because I find out that the board supports don’t line up with the mounting holes. No wonder the original supports were all loose, they had to be loose in order to fit.

Anyway, power on, the load cell error is now gone. Go into the +10 power on test mode, and adjust for the appropriate value – should be from 34 to 39, not 99. Great – next step, mount it on my test bench and try a low tension. Not good – when pulling at 20 lbs, I get 13 lbs actual tension, try 40 lbs – only get 26 lbs. Ok, I need to know whether or not the guy does tennis or badminton or both, so sent him an email.

He replied that he does tennis primarily. Ok, so today I started to perform an adjustment at 50 lbs, which is adjust VR2 to increase the tension, until it is almost right, then check the reading in test mode is from 34-39, if not – adjust VR1, which affects the VR2 setting. After doing a few iterations of this, I get it so that 50 lbs is actually pulling at 50lbs, and when I check at 20 lbs, I am getting 20 lbs – fantastic. At 65 lbs, it is also pulling 65 lbs. Tennis is usually from around 45 to 70 lbs, so job is done – I packed it up and it is ready to go back down to Melbourne.

If you are looking for relatively inexpensive couriers and are not transporting glass, I would suggest e-go.com.au – I got a quote to send this 10kg parcel down to Melbourne – it would cost $11.22 if I take it to the Parramatta depot. You can save 15% by sending depot-to-door, as opposed to door-to-door. Door-to-door is less convenient as you have to wait around for the courier to come and pick up the parcel. Since I go to Parramatta a few times a week, it is easy to take it to the Postnet shop which is the local depot for e-go.

One final photo – the failed ADC chip.

Hi John

I can see that you have had your “Magic fingers” on more than one of these tension heads, I have an issue with a similar from Eagnas (8000 Plus), and it seems that it´s using the same Electronics.

My display eventually turns off, but the rest is still working, do you have an idea what that could be?

You mention something about a Key press, and some error codes, do you have a list of these codes?

Best Regards

Hans

LikeLike

Hans, I have seen it happen once but the display came back before I could see what was causing it. The diagnostic is to press and hold the +10 key and then power on. It should display a number between 30 to 39. It is used during calibration of the load cell in the 8000 Plus.

LikeLike

Yes, the 8000 Plus does use similar electronics. I have repaired a number of those that had various faults, mostly mechanical.

LikeLike

Hi Again John, and thx. for taking the time to share a bit of your knowledge.

I think I located it to be the motor unit, when I remove that, simulating the sleigh to run by pushing the small switches in the correct order, everything Works, and the Electronics stays on.

By accident i came over a website with autoparts, and saw that the motorunit used was a windshield wiper engine. But there´s a lot of different type on the market, so the next big question is, which car, type, age and model should i buy to get the right crankshaft on the gearbox, and the right torque and voltage.

Do you have an idea?

Best Regards

Hans

LikeLike

Hans, the motor is essentially a 24V geared motor with the drive shaft at 90 degrees. I don’t have any information about the motor as I have not found it necessary to obtain replacements. Generally, if it doesn’t move the carriage, it is more likely the electronics drivers for the motor that is the problem, than the motor.

It might be better to take this discussion offline. I will send you an email – we can talk further.

-John

LikeLike

Hi John can you guide me on how to calibrate the Eagnas 3800 tension head

LikeLike

Lloyd, do you have the user manual that came with the Eagnas 3800? If not, you can try to contact your vendor to get a copy. Inside, it will explain how to calibrate – which will involve some adjustments.

LikeLike

Hi John, I came across this post when I was troubleshooting the error I have come across on my stringing machine. I have posted the error at Tennis Talk but haven’t recieved any suggestion yet: https://tt.tennis-warehouse.com/index.php?threads/tennis-stringing-machina-c06-error-code-troubleshooting-protennis-490i-gamma-6900-els.767417/. Not sure if you would have any clue what this error is related to? Any suggestion would be much appreciated.

LikeLike

Ben, I don’t know what the C06 error would be, but it seems to occur just after it starts pulling. It may be related to the tension measuring section, could be the ADC if it has one. All I could suggest is to contact Gamma and see what they might say.

LikeLike

Thanks a bunch, John. I’ve contacted Gamma to see what they say.

LikeLike