Sometimes for some reason or other, repair jobs may sit around for a while – here is one of those. I had been given a number of these monitors by my brother. They had been found thrown out in a loading dock in the city, probably from an office cleanup. The Benq GL2250 is a full HD monitor that is LED backlit and when I had the time to test them – I found that the reason these had been disposed of, was that part of the screen would go dim. It appeared to be part of the LED backlight that was going out, and turning the monitor off and on again, would often restore operation for a time.

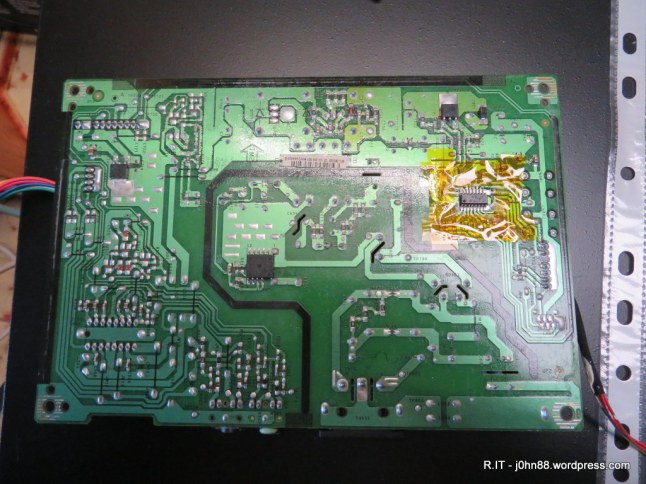

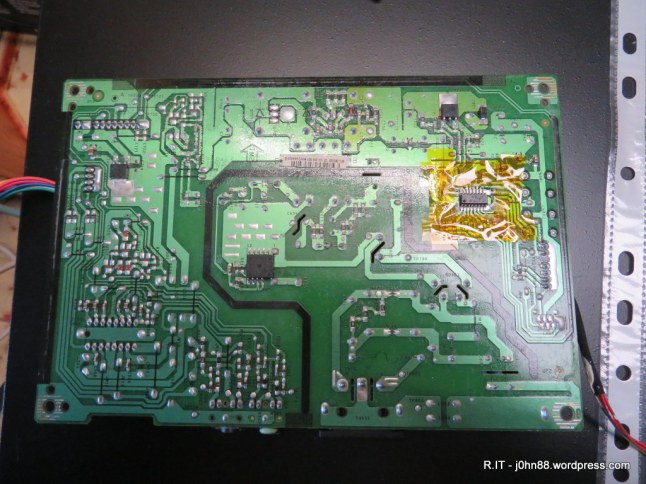

Since a 22″ monitor is still a reasonable size to use in the home office, and there were several of these with the same problem – I thought it would be good to repair them and get them working consistently. Certainly it would be worth a blog article. After disassembly, I was able to get to the power supply board, and on that board I found a MP3394 4-string White Led Driver integrated circuit.

I could access the cable from the power supply to the LED backlight – so decided to do some measurements, in the sense of leaving a voltmeter connected to one of the lines – to see what happened when parts of the screen dimmed out. After some of these measurements – which took time, due to the intermittent nature of the fault – I concluded that either the driver was at fault or maybe a faulty LED in the backlight.

Replacing the led in a backlight is not a simple operation, so I elected to try replacing the driver IC. On eBay, I found a vendor selling 5 pieces of these MP3394 devices for US$6.99 + US$1.00 for delivery – a reasonable price, so I ordered them. In time, the parts arrived and I put the parts together with the first printed page of the MP3394 datasheet. Then life happened – as it does. Just like that? Well, the reason was that a couple of weeks earlier, I was asked to go in for an interview for a challenging job, and was offered a full-time contract job that was for 6 months, but actually turned out to be nearly 3 years.

I could have come back to this repair job, couldn’t I? The new job was interesting, challenging and much of my time was spent working, so after getting home – I was tired, and didn’t feel like doing anything other than relaxing.

It isn’t really an excuse, but when I say life happens – it certainly does. I went on to do some studying in Cyber Security which I had been planning to do for over 10 years. This time I committed to do the training, CompTIA Security+, then CompTIA Cyber Security Analyst+ (CySA+), and only a couple of weeks ago, I completed CompTIA PenTest+. By completing, I mean studying for and passing the exams.

I also studied CCNA CyberSecurity Operations at TAFE, and since I did well in the final exam, I received a discount voucher for the actual Cisco exams. I then eventually sat for and passed both Cisco exams achieving the Cisco Certified CyberOps Associate certification. But I digress – I really wanted to talk about the repair of this BenQ monitor, but now you understand by what I mean that life happens.

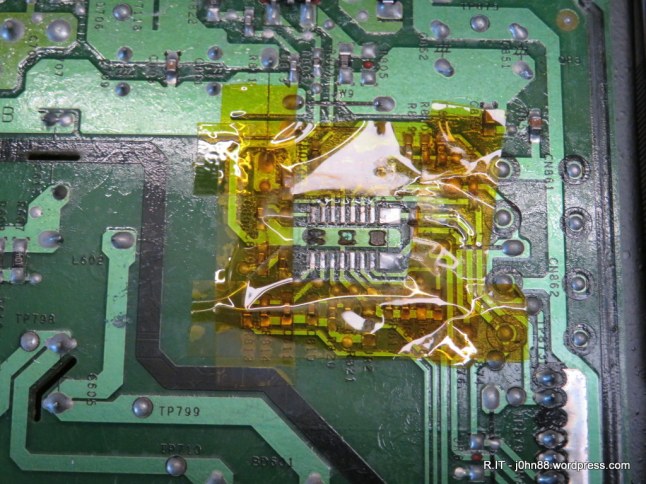

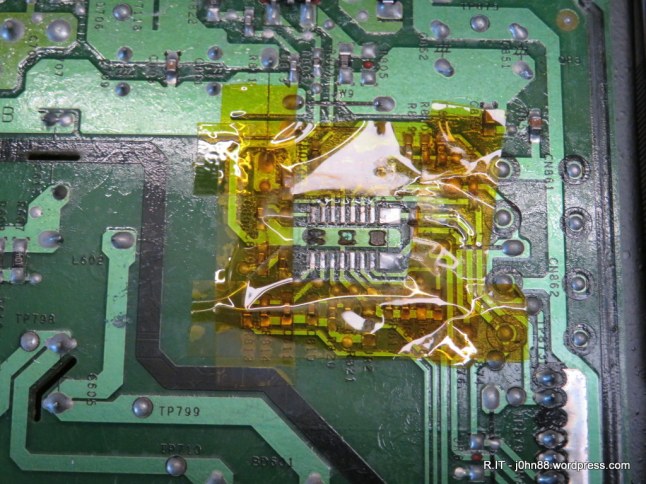

The MP3394 is a chip in a 16pin SOIC package. It is a surface mount chip, so I masked out the area around the chip with heat resistant tape – to protect the other parts nearby. After brushing some flux onto the pins, I applied the hot air gun onto the chip, and moved it around and around to get the chip and pins hot enough that it would then come off.

Actually it took a few minutes – I had the hot air gun set to 300 Celsius and airflow around 80%, which might have been too high – but it worked. After a bit of time, I could see and feel that the solder was molten, but the chip would not come off – and after another minute – it then came off. I was grabbing the chip with curved tweezers. When the chip was off, I found that there was three spots of glue under the chip, which is often used to keep the chip in place during flow soldering.

Then a quick cleanup using soldering wick, flux and the soldering iron to remove the left over solder, and leave a clean flat surface on all of the solder pads. Next step is to get the new chip in place, tack a couple of corners with solder to keep it in place, then solder each side of the chip. Soldering each side is done by putting more solder on the soldering iron tip, then wiping the tip down each row while holding the iron at an angle, so that the pins and pads are heated together and the flux allows the solder to flow and make a good join. With practice, you can get very good results.

I had a problem in that one of the pins on the IC was bent up, and I didn’t notice it when I was placing the IC – so good idea to double check before soldering. Since it was a single pin, I just pressed down with the soldering iron tip until it made contact with the pad. Then I visually inspected each joint with a 9x magnifier. To verify, I used a multimeter in the resistance measuring mode, and checked each pin was connecting to the solder pad test points, which were conveniently placed near each pin.

Next step will be to reassemble the monitor and check that the backlight fault is resolved, but the results of that will be in Part 2. To be continued…